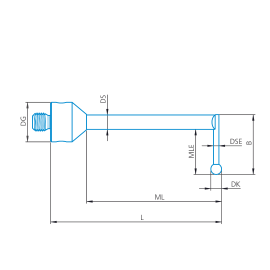

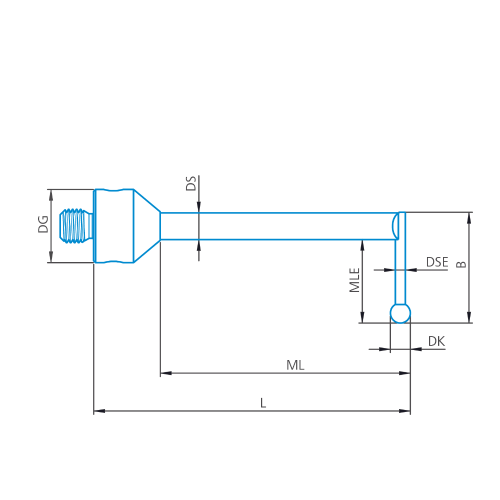

M5, L-styli, ruby sphere, straight, tungsten carbide shaft

L-stylus M5, DK5 L82.5

626115-5000-456

Application

L-styli for measuring undercuts and horizontal bores. M5 thread for VAST active scanning sensors.

- Spherical styli have the same probing behavior in every direction

- Ruby is the most common sphere material

- Ruby sphere available from 0.2 up to 12 mm

- Tungsten carbide shaft with high rigidity

- Straight shaft with longer measuring length

- Proven ZEISS quality through high-end manufacturing

Details

- product type

- Stylus

- Connection Type

- M5

- Ø Sphere (DK)

- 5,0 mm

- Length (L)

- 82,5 mm

- Application

- Tactile

- Ø Shaft (DS)

- 4,0 mm

- Ø Body (DG)

- 11,0 mm

- Meas. Len.

- 72,5 mm

- Stylus Type

- L-Stylus

- Ø2 Shaft (DSE)

- 3,0 mm

- 2. Meas. Len.

- 6,0 mm

- Stylus Tip

- Sphere

- Styl. Tip Mat.

- Ruby

- Shaft Mat.

- Tung. Carb.

- Width (B)

- 10,0

- Weight

- 19,3 g

- Software

- Software

Product note

Depending on the material of the stylus and the workpiece, wear or material deposits may occur. Therefore, regularly check your styli under a microscope and remember to clean them or replace them if damaged. Depending on the type and degree of contamination, a wide range of cleaning agents are available for cleaning. ZEISS application engineers recommend stylus cleaning wipes or microfiber cloths.